SEARCH

Enter your search term below:

Close

Enter your search term below:

WORLD LEADING BUSINESS SUPPORT

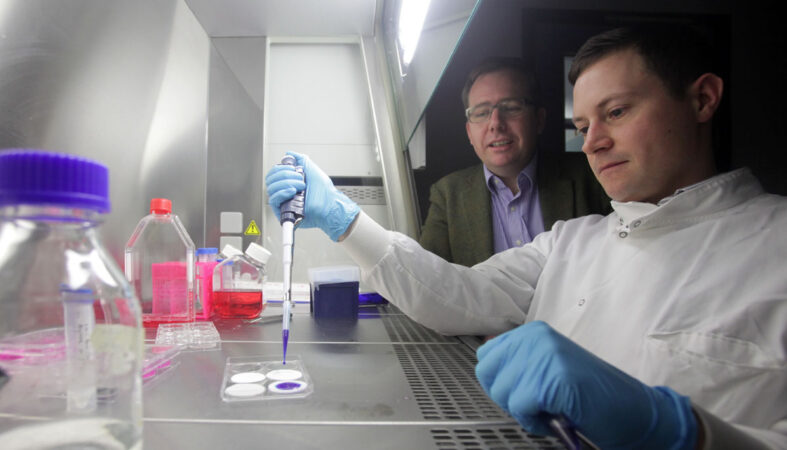

Atelerix, a spin-out from Newcastle University, is revolutionising the way that cells are stored and transported. Its simple, cell-friendly technology offers immediate access to stem cell therapies for patients suffering with a range of diseases from cancer to cardiovascular disorders and diabetes. The harvested cells can be stored and transported at room temperature, rather than the current system which relies on cryogenic freezing.

Innovation to Commercialisation of University Research (ICURe)

Funding: Grants: £590k; Equity £2.15m

2012

Technology invented

2014

BBSRC research grant

June 2016

Took part in ICURe programme

June 2017

Spun out from Newcastle University

2018

£425k seed funding round completed

August 2019

£220k Innovate UK grant received

2019

First sales in USA, Europe and India

2019

Opened laboratories in the Newcastle Biosphere

2019

Atelerlix technology accepted into a clinical application

2020

First sales in China

May 2020

£600k Funding round completed

September 2020

£140k Innovate UK grant received

2020

£70k grant from UK Innovation and Science Seed fund (UKI2S)

March 2021

Partner on £400k Innovate UK grant

January 2022

£160k Innovate UK grant received

February 2022

£425k Funding round closed

May 2022

£100k DASA sponsored project started

August 2022

CytoStor™ cell preservation product launched

March 2023

Commercial agreement with RAFT Solutions signed

April 2023

LeukoStor™ for the preservation of apheresis material launched

“The technology we invented in 2012 was based on an observation from the lab that alginate encapsulation could keep cells alive. At first, our objective was just proof of concept, we worked to optimise the technology to allow the storage and distribution of cells in the cell therapy supply chain. We secured our first grant from the Biotechnology and Biological Sciences Research Council (BBSRC) in 2013.”

“In those early years, we were very much focused on R&D, on cell storage, but we weren’t sure how to commercialise it. The ICURe programme was the perfect vehicle to help us answer these questions. It allowed us to identify and map the target markets, as well as start to consider more of the product development side. We started to think how this technology is going to be used by others and how it would be implemented. Through ICURe we received direct feedback and adjusted our attention to the cell storage kit accordingly. ICURe helped us to develop a ‘kit concept’.”

“In 2019 we moved into our new facilities in Newcastle, and our focus shifted to product development and products for drug discovery. We launched our ‘WellReady’ system that incorporated our self-storage technology and launched ‘BeadReady’ and ‘TissueReady’ for different applications.”

“COVID was challenging, but it gave us the opportunity to investigate how our technology could be applied to preserve oral and nasal pharyngeal swabs to help with the pandemic. The results from the trials showed that we can preserve functional viruses, which has led to several other potential applications – a positive effect we hadn’t expected. We have now extended the preserving of live viruses to several different virus types, including lentivirus, which has led to further applications in biotech and viral gene therapy, and even in biowarfare monitoring – which is another new application that we didn’t anticipate.”

“We continue to work on generating new products and extending the validation of existing products for different applications. We focused on blood products, both cell and gene therapies, for research, drug discovery and clinical trial monitoring. We have developed a product to preserve leukapheresis material, for immune cell therapies for oncology treatment. We have further modified this to preserve whole blood to preserve liquid and solid biopsies. In addition, we have further developed further ‘TissueReady’ for the preservation of tissues for cancer biopsies, for drug discovery and research to biobanking.”

“We have also moved into preserving germ plasm (semen and early embryos) in a project for cattle breeding, which involves collecting and delivering infield samples in very large expanses of land for shipment throughout Canada.”

“We have brought in automation in our manufacturing process to streamline and expand our manufacturing capabilities for the provision of materials for research use. We are growing our quality management system to an appropriate standard to enable us to have our own general manufacturing Practice (GMP) and manufacture GMP compliant products for regulated use.”

“We now have an extensive product range – our aim is for our products to be the gold standard for any non-cryo stabilisation of cell products. We want to radically improve the current system particularly in the cell therapy field, to in turn improve the success rates of cell therapies for those patients who really need them.”

Steve Swioklo, CSO & Co-Founder

Atelerix Ltd

Close